The Fédération Internationale de l’Automobile (FIA), the global body that oversees motor sport, is expanding its use of Siemens digital twin technology as part of a new partnership. Siemens has joined the FIA’s Global Partnership Programme and will act as the official digital twin sponsor.

The FIA will rely on Siemens’ Xcelerator portfolio to help design and test aerodynamic concepts for single-seater race cars, from Formulas 1 to 4. With Siemens’ Designcentre NX software, engineers can build and adjust virtual models and run computational fluid dynamics (CFD) simulations. These let the FIA optimise performance and safety and cut down on the need to build physical prototypes for wind tunnel testing.

Since 2022 the FIA’s aerodynamics team has produced over 14,000 computer-aided design (CAD) parts and run over 10,000 CFD tests using Siemens’ tools. Shifting much of this work into a digital environment has helped lower the carbon footprint of car development, the foundation states.

FIA’s vision for racing

Jason Somerville, the FIA’s head of aerodynamics, said, “Siemens gives us the precision tools to design and test complex aerodynamic concepts virtually, reducing environmental impact while improving performance and safety. The technology is key to ensuring that racing remains closer, fairer, and more competitive.”

Beyond the FIA’s work with Siemens, Formula 1 push the limits of digital engineering. Recent studies in 2025 highlight how CFD, digital twins, and machine learning are changing the way race cars are designed and refined.

One project led by Alpine F1 and Oxford Brookes University tested changes to a car’s diffuser using CFD tools. Small tweaks, like adding a lateral vane, delivered big gains: about a 13% boost in downforce and a 5% cut in drag compared to the baseline model. The results show how even subtle design adjustments can have a measurable impact on performance when explored in a virtual environment.

Front wing design is also seeing a shift. A study published in 2025 combined traditional CFD runs with a physics-informed neural network to speed up predictions of aerodynamic behaviour. The model achieved high accuracy – almost 97% for drag and 98% for lift – and reduced the time needed to evaluate new wing concepts. This kind of hybrid virtual/physical approach allows teams to run through more design ideas in less time, a key advantage under Formula 1’s strict cost and testing limits.

One constructor reports aiming for around 1,000 CFD simulations per week, supported by faster post-processing tools that can give results to engineers nearly instantly. The capability to look into thousands of options online, rather than building physical prototypes, gives teams more chances to find competitive advantages.

CFD also plays a role in preparing for the 2026 regulatory changes. Analysts have used simulations to predict how new aerodynamics rules will alter airflow around the diffuser and wings, helping teams prepare strategies before the first car reaches the track.

Next steps in the Siemens digital twin partnership

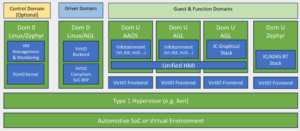

The FIA will increase its use of Siemens’ Teamcentre® X software for managing product data and collaboration in championships, and expand its use of Siemens’ simulation tools, including Simcentre® X, Simcentre™ Amesim™, Simcentre™ STAR-CCM+, and Simcentre™ HEEDS.

Through its Global Partnership Programme, the FIA works with organisations that share its goals around innovation, safety, and sustainability in motor sport.

See also: IoT in 2025: Digital twins, mesh networks, VR, and more

Want to learn more about IoT from industry leaders? Check out IoT Tech Expo taking place in Amsterdam, California, and London. The comprehensive event is part of TechEx and is co-located with other leading technology events, click here for more information.

IoT News is powered by TechForge Media. Explore other upcoming enterprise technology events and webinars here.